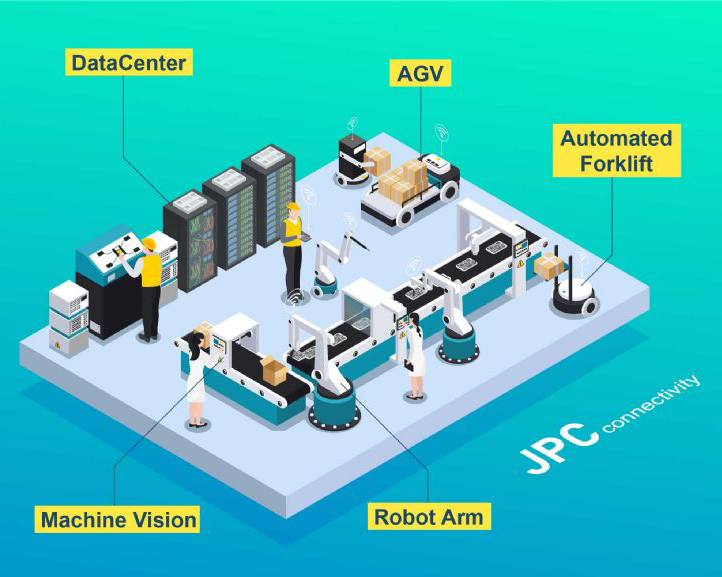

Robots come to mind when people talk about factory automation. Smartization has become the most critical consideration in the global manufacturing industry’s strategic planning. Robotics developments have taken on a whole new look thanks to emerging technologies including artificial intelligence (AI), 5G communication and Industrial Internet of Things (IIoT). For example, AI-capable robotic arms are widely used in factories for automatic optical inspections (AOI). Autonomous mobile robots (AMR) integrating 5G and AI play a vital role driving the digital transformation of the logistics and warehousing industries.

Robotic arms and AMR are just elements of smart manufacturing systems. The creation of smart manufacturing systems with the design and performance that are tailored to perfectly suit user needs requires cross-industry collaborations by experts from different backgrounds. A group of five high-tech leaders each with established presence in their own field including Chenbro, FSP Group, Coretronic, JPC and ADLINK have formed a strategic alliance. By contributing their expertise respectively in server casing, power supply, display technology, connectors and wire harness as well as embedded systems and edge computing, they aim to provide total solutions to manufacturers embarking on digital transformation. Their joint efforts will help Taiwan’s manufacturing sector accelerate digital transformation and capture upcoming smartization opportunities.